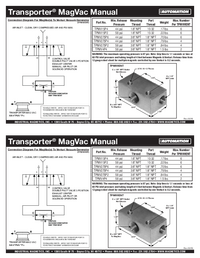

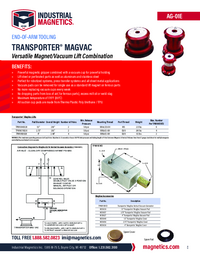

Transporter® MagVac

Transporter® MagVac is a combination of vacuum technology and air-actuated magnetic tooling designed for lifting and holding ferrous steel in stamping, blanking, press-to-press transfer, and related applications.

OVERVIEW

The Transporter® MagVac difference is the incorporation of vacuum technology, similar to vacuum cup grippers, which makes the Transporter MagVac the most universal End-Of-Arm-Tooling available. With part-holding values higher than traditional vacuum- and more efficient and accurate than vacuum or grippers- the Transporter® MagVac is the solution that eliminates tool-changeover and costly downtime.

The Transporter® MagVac will lift and hold all shapes and types of steel- from brass and aluminum to ferrous and stainless, perforated, oily, or painted. The integrated magnet/vacuum design is a million-cycle tested for endurance. When in use on ferrous steel, it incorporates a Fail-Safe feature so that in the event of air loss, parts will not release.

- No more replacing vacuum cups every week

- No more parts slippage and die damage due to part misplacement

- No more dropping parts when there is a loss of shop air

- No more dropping parts because of excess mill oil or weld slag

- No more tooling change and downtime when a new part shape is in the process stream

For efficient, accurate, and longer-lasting End-Of-Arm-Tooling that provides a quick return on investment, choose the Transporter® MagVac.

Please Note: TheVent (Part# TPMVVENT) is not necessary if other means of creating a vacuum are in use. The vent will operate the magnet and the vacuum cup simultaneously when lifting ferrous metal, providing extra lifting power. However, when using the magnet only, a Vent is not necessary. If lifting non-ferrous metals, the vent is required.

Transporter® MagVac Products

| SKU | Diameter | Height | Weight | WLL- Working Load Limit | In Stock |

|---|---|---|---|---|---|

| Switch to product variant SKU TPMV040028 | 1.5 | 2.16 | 0.22 | 7 | |

| Switch to product variant SKU TPMV070028 | 2.75 | 3.15 | 0.84 | 45 | |

| Switch to product variant SKU TPMV100028 | 4 | 2.48 | 1.5 | 38 | |

| Switch to product variant SKU TPMV15C | |||||

| Switch to product variant SKU TPMV15VP | |||||

| Switch to product variant SKU TPMV275C | |||||

| Switch to product variant SKU TPMV275VP | |||||

| Switch to product variant SKU TPMV4C | |||||

| Switch to product variant SKU TPMV4VP | |||||

| Switch to product variant SKU TPMVVENT2 |

More products for End Of Arm Tooling

I'd like to speak to a magnetics expert

Have questions you’d like to speak to an IMI team member about? Fill out the contact form with the information you have, and a member of our sales team will be in touch soon. We can’t wait to chat.