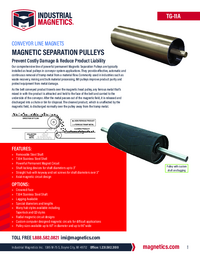

Heavy-Duty Magnetic Pulley Separators

Prevent costly damage and reduce product liability with Magnetic Pulley Separators in your product conveying line.

OVERVIEW

Our comprehensive line of powerful permanent Magnetic Separation Pulleys are typically installed as head pulleys in conveyor system applications. They provide effective, automatic, and continuous removal of tramp metal from a material flow. Commonly used in industries such as waste recovery, mining, and bulk material processing, IMI pulleys improve product purity and protect equipment from metal damage.

As the belt conveyed product travels over the magnetic head pulley, any ferrous metal that is mixed in with the product is attracted and held to the face of the belt and carried to the underside of the conveyor. After the metal passes out of the magnetic field, it is released and discharged into a chute or bin for disposal. The cleaned product, which is unaffected by the magnetic field, is discharged normally over the pulley away from the tramp metal.

Benefits

- Removable steel shaft

- T304 stainless steel shell

- Powerful permanent magnet circuit

- Shaft locking devices for shaft diameters up to 3”

- Straight hub with keyway and set screws for shaft diameters over 3”

- Axial magnetic circuit design

- Crowned face options

- T304 stainless steel shaft available

- Lagging available

- Special diameters and length options

- Many hub styles available including Taperlock and QD styles

- Radial magnetic circuit design options

- Custom computer-designed magnetic circuits for difficult applications

- Pulley sizes available up to 60” in diameter and up to 96” wide

More products for Head and Tail Pulley Magnets

I'd like to speak to a magnetics expert

Have questions you’d like to speak to an IMI team member about? Fill out the contact form with the information you have, and a member of our sales team will be in touch soon. We can’t wait to chat.