Why is it Important to Test Magnet Strength?

Industrial magnets play a vital role in maintaining food purity and metal-free production. Essential for consumer safety and regulatory compliance, they can weaken over time, risking contamination incidents. Magnet strength testing is crucial for food processors to monitor magnet effectiveness and initiate maintenance to prevent hazards.

Gauss Tests and Pull Tests are common industry methods for assessing magnet strength. Both methods indicate magnet performance and companies can use them together or separately to assess the operational status of the equipment. Companies may take a definitive stance, opting for one test over the other. Industrial Magnetics is committed to continuously improving magnet quality, service, and processes. As part of this dedication, we are eager to explore and share our insights on each process.

Pull Test Overview

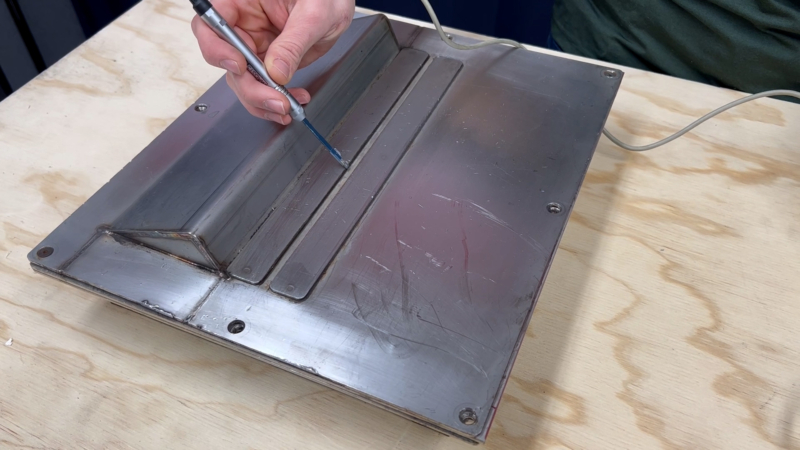

A pull force gauge is a tool that measures how much force it takes to pull a piece of steel vertically away from a magnet. The force scales may be a mechanical spring scale, or a digital gauge. Ensure the magnet’s surface is cleaned before beginning the pull test. Any debris that can introduce an air gap between the test piece and the magnet can significantly reduce the gauge measurements. Select the appropriate scale, test piece, and consider the need for an air gap. An example of this would be if there is a belt or other equipment that will provide a designed air gap in operation. Steel test balls are used when possible to measure the magnetic field strength directly on magnetic surfaces as they will migrate to the closest magnetic pole. For pole space distances greater than one or two inches, the option is to use test plates, ensuring they bridge from North to South Pole and are centered.

Attach the test piece to the gauge and carefully position the test piece on the magnet’s surface. Note that the test pieces may exhibit significant pull, such that the surface of the magnet can be dented or damaged. The scale is then pulled evenly away from the magnet surface in a direction that is perpendicular to the magnetic face until the test device breaks away. The peak is measured and recorded, and the test is repeated multiple times in the same or alternate random locations. Once the tests have been completed, calculate the average of the pulls. The average value represents the magnet’s pull strength. Compare the results with the factory baseline measurements to determine if service or replacement is required.

The tester measures the force required to overcome the magnetic attraction and separate the test piece from the magnet. A pull test methodically evaluates the strength of a magnet, informing future decisions.

Gauss Test Overview

This magnetic strength test measures the magnetic field direction and strength produced by a magnet using a gauss meter – also referred to as a magnetometer. This device consists of a sensor probe and display unit, precisely designed for measuring magnetic flux density - the concentration of magnetic field lines – when placed near a magnet.

There are two alternate gauss meter probes: axial and transverse. Transverse probes are best suited for evaluating flat surfaces: axial probes can provide more flexibility for alternate geometries or confined spaces. The gauss meter probe is placed near or on the magnet’s surface to record the magnetic field strength readings displayed on the meter. This process should be repeated across the magnet’s surface and gap areas to capture a picture of the magnetic field’s distribution at various distances and angles. The recorded measurements provide insight into how the magnetic field strength varies with distance and direction from the magnet.

It is customary to record peak values, and digital gauges typically have a setting to help you achieve that. After collection all data, analysis will provide an understanding the magnetic field strength, an assessment of how the field strength varies with distance from the magnet, and a comparison of the results to standards or specifications. The results guide decisions in operational processes.

Which Test is Better?

This is a challenging question that is asked in the industry to simplify a complex matter. Each method has its merit, but for owners, it should come down to separation effectiveness.

Pull Tests:

- Provide an objective measure of breakaway force using a standard test piece (validation)

- Can be subjective based on operator and technique (Gauge Repeatability and Reproducibility)

- Good for comparison for factory baseline

Gauss Tests:

- Provide empirical value to compare with specifications (verification)

- Can be viewed as more theoretical than practical

- Good for comparison to factory baseline

These methods gauge how effectively a magnet can capture and eliminate ferrous contaminants from the product stream. The processing is influenced by magnet strength, flow rates, particle chemistry, geometry, and bulk density. The method chosen should be based on the customer’s specific situation, requirements, and how the team of local experts will evaluate performance in operation.

Debating whether Pull Tests or Gauss Tests are better may not lead to the meaningful conclusions sought out. Instead, we should aim for practicality and establish suitable performance indicators. Extensive debate can hinder research and delay results that lead to the most efficient solution for your metal separation needs.